Introduction

When it comes to selecting a checkered plate for your project, you’re faced with a pivotal decision: aluminum or stainless steel? Both materials offer unique advantages and characteristics that cater to various applications. In this article, we’ll delve into the key differences and benefits of aluminum checkered plates versus stainless steel checkered plates, helping you make an informed choice that aligns with your specific needs.

Durability and Corrosion Resistance

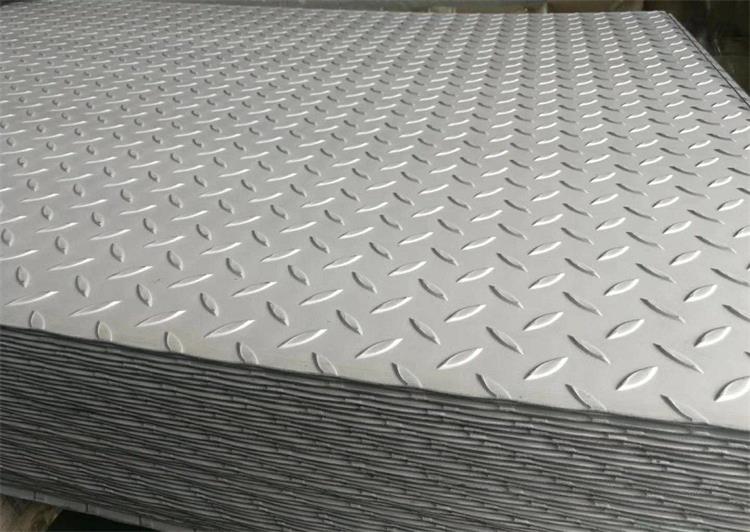

Stainless steel checkered plates are renowned for their exceptional corrosion resistance, making them an excellent choice for environments exposed to moisture, chemicals, and extreme weather conditions. On the other hand, aluminum checkered plates also boast good corrosion resistance, particularly in more mild environments. While both materials offer protection against rust and degradation, stainless steel excels in more aggressive settings, making it ideal for marine, chemical, and industrial applications.

Weight Considerations

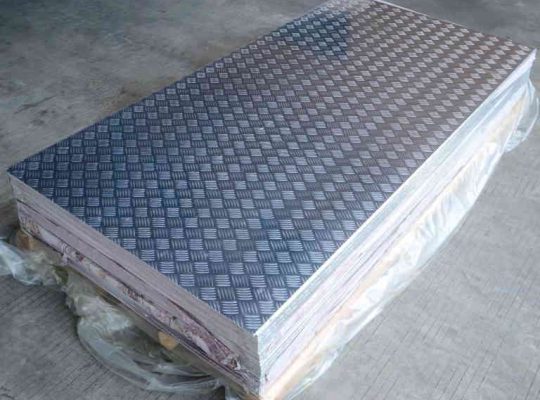

One of the primary advantages of aluminum checkered plates is their lightweight nature. They’re perfect for applications that require structural strength without adding excess weight, such as vehicle flooring and aerospace components. Stainless steel, while durable, is significantly denser and can be better suited for applications where weight isn’t a critical factor, like architectural accents and heavy machinery parts.

Aesthetic Appeal and Finish

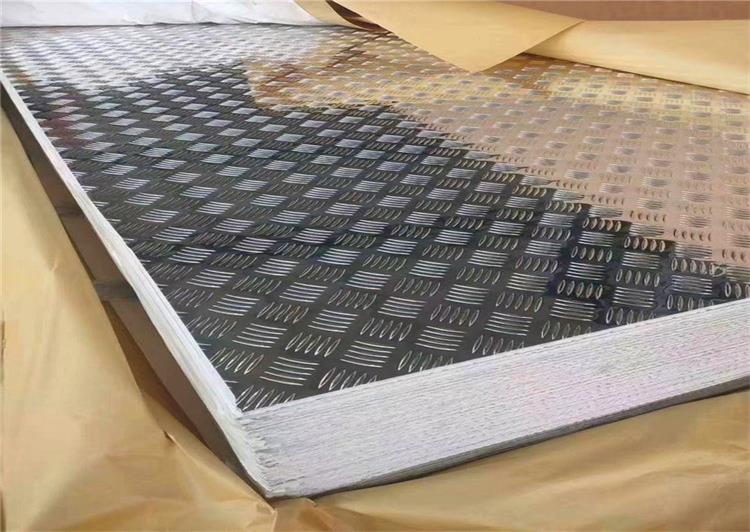

Stainless steel checkered plates often boast a sleek, polished appearance that exudes a modern and luxurious vibe. This makes them a popular choice for architectural designs and interior decor elements. Conversely, aluminum checkered plates offer a more utilitarian appearance, making them suitable for industrial flooring and heavy-duty applications.

Cost Considerations

When it comes to cost, aluminum checkered plates generally tend to be more budget-friendly than their stainless steel counterparts. This affordability can be a deciding factor for projects with strict budget constraints. However, it’s important to consider the long-term benefits of stainless steel’s durability and resistance to corrosion, which might outweigh the initial cost difference in certain applications.

Heat Conductivity and Electrical Properties

Aluminum’s exceptional heat conductivity makes aluminum checkered plates a suitable choice for applications requiring heat dissipation, such as cookware and automotive components. Stainless steel, while offering good thermal conductivity, might not match aluminum’s efficiency in this regard. Additionally, stainless steel offers excellent electrical conductivity, making it a preferred choice for applications requiring conductivity, such as electrical enclosures and grounding systems.

Conclusion

The decision between aluminum and stainless steel checkered plates hinges on a range of factors, including the application’s environment, weight requirements, aesthetics, cost considerations, and functional attributes. Both materials have their own distinct advantages, and understanding their characteristics helps in making an informed choice that aligns with your project’s unique demands.

Whether you prioritize corrosion resistance, weight savings, aesthetic appeal, or thermal conductivity, the choice between aluminum and stainless steel checkered plates ultimately depends on finding the perfect balance for your specific needs.

Aluminum Checker/Tread Plate On Hot Sale

1060 aluminum checker plate

3003 Non-slip aluminum floor plate

5754 aluminum floor tread plate

5052 tread plate

5052 diamond aluminum plate

6082 checkered plate

6061 T6 diamond tread plate

6061 perforated aluminum plate/sheet

6061 aluminum five bars tread plate